Sterile Ophthalmic Manufacturing

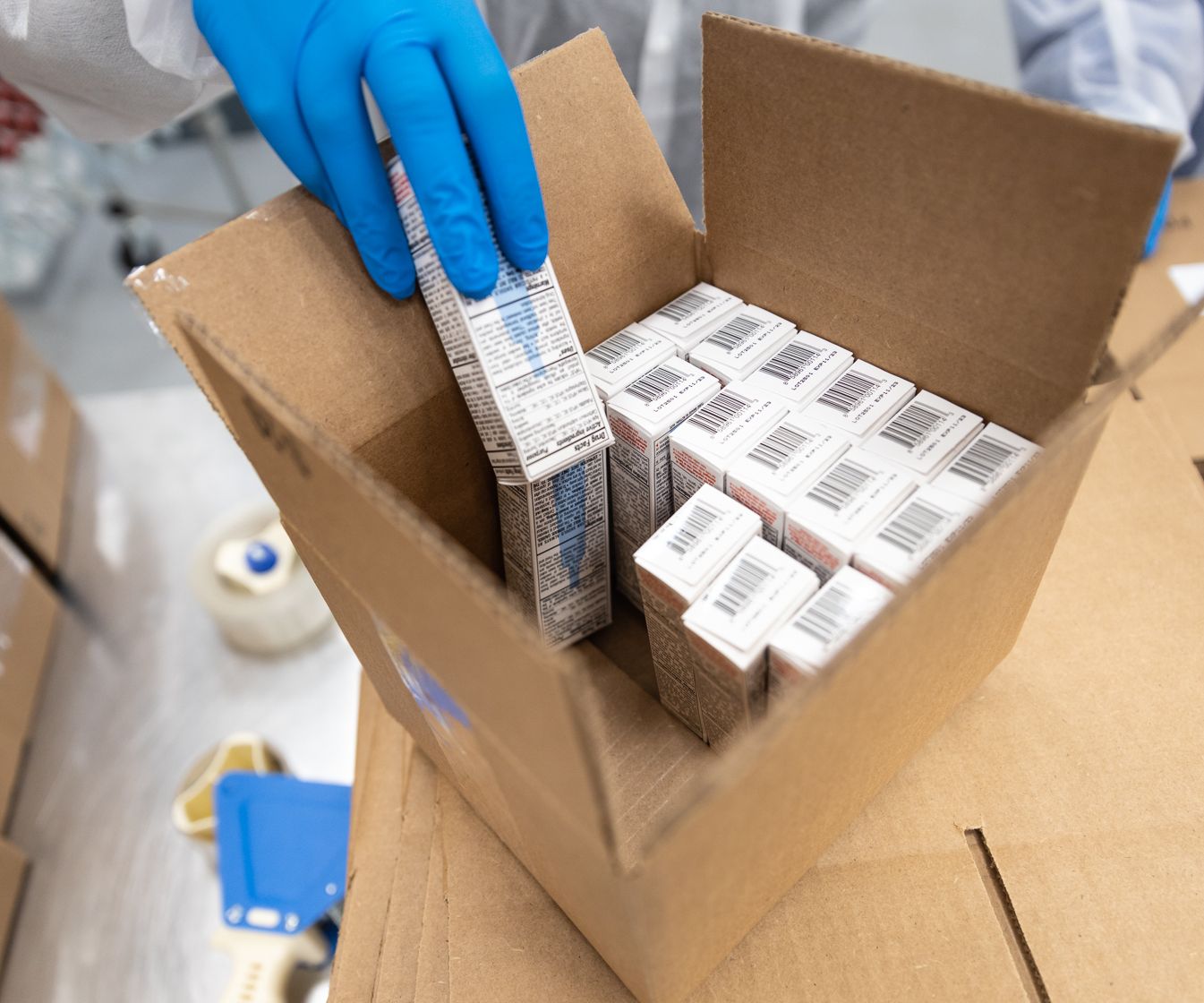

Our manufacturing facility is built for the purpose of manufacturing sterile ophthalmic products including solutions, suspensions, ointments, gels, and trusted aseptic capabilities. We package in metal and laminate tubes, three-piece bottles (3-20 ml), multi-dost preservative free bottles, and unit of use strips.

High Potent Capability

Our facility can also handle High Containment of potent compounds through a closed manufacturing system. We currently have multiple dedicated processing suites and supporting infrastructure, along with a dedicated packaging room along with a remote documentation room. When a chemical is introduced to our facility, we ensure that multiple studies are performed to ensure that there is no contamination.